Rubber floor matting remains one of the safest flooring options in homes, offices, workshops, and various sports facilities. Here I will elaborate on why rubber floors are very safe and are a floor of choice.

What are the components that makeup Rubber?

Rubber was first discovered a very long time ago in the 16th century, made from a natural source called rubber tree latex. Nowadays because of technological advancement, most rubber is being made from synthetic and recycled vehicle tyres. However, recycled rubber produces an unpleasant odor not suitable for people with respiratory problems whereas rubber made from virgin PVC components and recycled PVC cables is odorless.

Installing Rubber Floor Matting

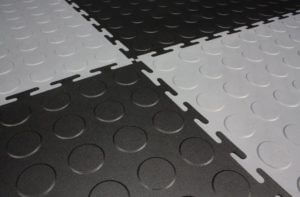

- Rubber floor matting can be installed over any rigid and level surface. It can be installed on concrete floors, and ceramic or porcelain tiles. Interlocking rubber tiles can be interlocked together with no need for adhesive. however, gluing or screwing it down will increase the durability

- Rubber floor matting is now becoming popular for modern industrial and sporting landscapes as it is durable and a good flooring investment

- Rubber floor matting is convenient to install and can be tailor-made to fit your desired shape or spread over as sheets.

- Rubber floor matting is cheaper by about 30% as compared to other traditional flooring expensive alternatives such as cement and ceramic tiling.

When Should Rubber Floor Matting Be Avoided

- There are some spaces where rubber flooring is not commended and should not be avoided. Areas that are not rigid and level will result in bulges and crumples and users risk falling when walking or working on them.

- It is also not recommended to use rubber flooring when the surface has significant breaks or openings. Rubber with time tends to follow the shape of the surface, so a subfloor with cracks and breaks is not ideal as the rubber floor will build ridges and creases thereby making the floors not safe.

Do I Need Underlayment for Rubber Floor Matting

- Underlayment is a thin material or sheet used underneath roof materials or placed underneath other flooring materials. Underlayment helps to absorb the unevenness or deficiencies of the underlying floor when spread. It gives the flooring material extra support and smoothness.

- Underlayment also helps to reduce sound noise, protect floors from harmful moisture and provide thermal insulation.

- However, there is no special underlayment necessary for rubber flooring it just requires the surface to be rigid and level.

Characteristics of Rubber Flooring

By nature rubber is a sound absorber

It can absorb sounds from footsteps and wheeled trolleys.

Excellent slip resistant

Even if the surface has any moisture rubber flooring has a very good grip to provide extra safety.

Waterproof

Suitable for areas prone to moisture, it does not allow any moisture from underneath to the top surface

Durable and Resilient

Rubber flooring can withstand high traffic and heavy usage, it can also withstand different temperatures and weather.

Rubber flooring is versatile

Rubber flooring be accommodated different types of activities and pressures, it does not easily wear and tear

Easy to Clean and Maintain

Low maintenance cost ne special materials needed cleaning it

Excellent Impact Absorber

- Able to withstand heavy impacts it does not break and crack when something heavy or hard is dropped on it.

Easy to Install

- Installing rubber flooring is simple you can even do it yourself, no special expertise is necessary you just need to follow a few instructions that come with the flooring

Chemical and Stain Resilient

Does not easily stain and is affected by various chemicals

Conclusion

Rubber is the most ideal flooring option suitable for various surfaces ranging from homes, bathrooms, recreational facilities, offices, playgrounds, retail outlets, industries as well as workshops. I would highly recommend investing in rubber flooring for the reasons highlighted above.

Rubber from recycled material has an unpleasant odor in the first few weeks which can last up to 8 weeks. However, there are now some chemicals that can be used to fend off the odor.

The last drawback is that rubber smells in the first few weeks of installation. The odor can last up to 8 weeks. However, the good news is that we now have chemicals that can be used to fend off that smell.

For your rubber floor matting requirements get in touch with our team for a professional assistance