Factory Flooring

The most difficult decision for factory owners and managers is how to decide on the best factory flooring. There are many choices the decision-makers can decide on depending on various factors at their disposal.

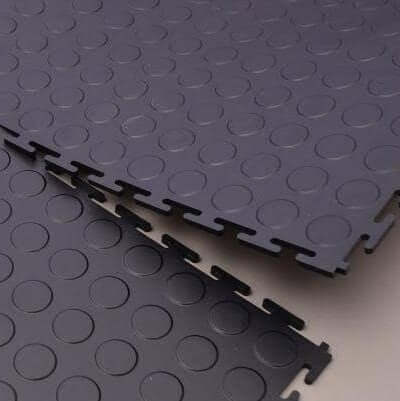

Whether industries or steel factories both need the strongest flooring which lies in the epoxy and rubber interlocking tiles. Though Pvc interlocking tiles are much more cost-effective than epoxy.

Certain parts of factory flooring without vehicular movements can be installed with adhesive free hence helping environmental friendliness.

We as Pvc floor Tile Company specialize in Rubber Interlocking mats; we will articulate why you should use the less costly but effective solution.

How to decide on the best factory flooring concept

- Material – Pvc

- Weight – 5.2kg

- Tile Size: Length 500mm, Width 500mm, Thickness 5mm

- Relative Density – 1.53 g/cm3

- Tensile Strength – 13.2 MPa

- Fire Retardancy – 6.2 Seconds

- Temp(0C) – 155/150/145/140

- Budget: The budget for factory floors plays a major role in the type of flooring one should consider. The cost of flooring should include installation and after-installation maintenance

- Durability: By nature, factory flooring durability should be considered. Though the budget factor will impact durability

- Factory floor purpose: The activities that are being carried out in the fact. Heavy-duty usage such as heavy vehicular movement requires factory flooring to be made of epoxy, Alternative rubber interlocking tiles should be considered, but most flooring such as wooden, porcelain, and others will not work.

- Factory floor traffic: Factory traffic will vary from place to place but the heaviest floor traffic needs to be considered if the budget allows the flooring can be uniformly applied.

- Acoustic and fire retardant

- High tensile properties

- Dust reduction

- Resistant to most chemical components

- Easy to maintain and cleaning

- Non-slip properties

- Suitable for Vehicular movement

- Easy install, uninstall, and reinstall

- Suitable for DIY Installation

- Can be recycled when its life span ends and re-used again for the same purpose

- Provides cost effectiveness and hence continue to contribute to lowering maintenance costs

- It’s a must to use recommended adhesive A660 when there are vehicle movements such as forklifts, motor vehicles, trucks, etc. and pallet jacks dragging

- Use of Pvc Pvcocity Sealer in wet areas such as bathrooms. A once-off procedure

- Recommended to use Pvcocity Polish for a shiny look and feel every 3 -6 months depending on the traffic

- Recommended to use adhesive for long durability in non-vehicular

- Non-adhesive only applies to tiles that are 7mm and above

- Consider the use of edging strips for a fine modern finish and last tile row durability

- Non-use of color Tiles in heavy traffic areas

International Rubber Mats

We don’t only focus on South Africa, we also supply rubber mats in other countries such as:

Rubber Mats in Botswana – Rubber Mats in Durban – Rubber Mats in Cape Town – Rubber Mats in Kenya – Rubber Mats in Nigeria – Rubber Mats in Namibia