Rubber is a product that was first discovered centuries ago by an American scientist and has formed a crucial part of human life and helps solve most of the life problems from making rubber mats, seals, tires, balls, and many more products.

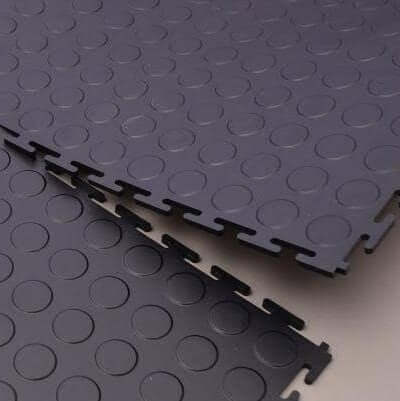

Would like to focus on one part of rubber which is rubber mats. Rubber flooring are mostly made from pvc rubber tiles.

Advantages of rubber mats.

There are many advantages that rubber mats provide to users. Herewith are some of the pros of having rubber mats.

- High durability

- Chemical resistant

- Water resistance

- Resistance to tearing

- Low water absorption capabilities

- Fine cell structured

- Resistance to abrasion

- Anti-slip

- Anti-thermal properties

- High acoustic properties

- Good aesthetic appearance

- Hardness

- High tensile strength

- Highly flexible and elongation

If anyone checks on the above properties it is the best material to make rubber mats. Below are the properties of pvc interlocking rubber mats.

Product Spec

| Final Product Test Results for heavy metals and other chemicals | |||

| PVC – Pass | |||

| El | PPM\% | +/- | |

| Sn | 104 | 27 | |

| Fe | 84 | 8 | |

| Cr | 39 | 7 | Pass |

| Sr | 17.9 | 1.2 | |

| Zn | 771 | 12 | |

| Cd | ND | < 44 | Pass |

| Pb | ND | < 2.7 | Pass |

| As | 4.8 | 0.4 | |

| Ca | > 10% | ||

| Cl | > 10% | ||

| Hg | 7.1 | 0.9 | Pass |

| Ti | 405 | 38 | |

| Br | 4 | 0.6 | Pass |

| Ba | 411 | 85 | |

RAW MATERIAL PRODUCT DATA SHEET |

||||

| DESCRIPTION: GP INSULATION AND SHEATHING COMPOUND | ||||

| APPEARANCE: BLACK PELLETS WHICH GIVE A SMOOTH SURFACE FINISH ONCE EXTRUDED | ||||

| PROPERTIES | UNIT | TYPICAL VALUES | TEST METHOD | |

| PHYSICAL | ||||

| RELATIVE DENSITY | g/cm3 | 1.53 | SABS METHOD 649 | |

| B S S SOFTNESS | BSS | 20 | BS2782 METHOD 365A | |

| SHORE “A” | ” A “ | 91 | CONVERSION TABLE 3 | |

| MECHANICAL | ||||

| (unaged) | ||||

| TENSILE STRENGTH | MPa | 13.1 | SABS METHOD 503 | |

| ELONGATION | % | 208 | SABS METHOD 504 | |

| (aged) (168 hrs @ 100 0C) |

||||

| TENSILE STRENGTH – RETAINED | % | 112 | SABS METHOD 507 | |

| ELONGATION – RETAINED | % | 91 | ||

| LOSS OF MASS MAXIMUM | mg/cm2 | 0.3 | SABS METHOD 510 | |

| OIL IMMERSION | ||||

| RETENTION OF TENSILE STRENGTH | % | SABS METHOD 510 | ||

| RETENTION OF ELONGATION AT BREAK | % | SABS METHOD 511 | ||

| RESISTANCE TO PETROLEUM | ||||

| VARIATION IN VOLUME | % | SABS METHOD 1017 | ||

| SIGNS OF STICKING / CRACKS | SABS METHOD 150 | |||

| CHANGE IN COLOUR | ||||

| LOW TEMPERATURE | ||||

| COLD BEND | 0C | -30 | SABS METHOD 501 | |

| COLD FLEX | 0C | BS2782 PART 1:METHOD | ||

| ELONGATION | % | BS6469 SEC .,14.992 | ||

| IMPACT | 0C | BS6469 SEC .,14.993 | ||

| HIGH TEMPERATURE | ||||

| HEAT SHOCK | 0C | 150 | SABS METHOD 500 | |

| HEAT DEFORMATION | ||||

| HOT PRESSURE TEST | % | 34 | ||

| ELECTRICAL | ||||

| VOLUME RESISTIVITY AT 20 0C | ohms cm | HEWLETT PACKARD | ||

| FIRE RETARDANCY | ||||

| RESISTANCE TO BURNING | seconds | 6.1 | SABS METHOD 502 | |

| LIMITING OXYGEN INDEX | % | |||

| RECOMMENDED PROCESSING TEMPERATURE’S. (0C) 155/150/145/140

Use of rubber mats/ Application for rubber matting |

||||

There are many uses of rubber mats worldwide. Below is the best list of rubber mats applications

- Gym flooring

- Garage flooring

- Workshop flooring

- Warehouse flooring

- Factory flooring

- Tyre Centre flooring

- Airport walkway flooring

- Kids play Centre flooring

- School flooring

- Pre-school flooring

- Retail flooring

- Hospital flooring

- Patio flooring

- Studio flooring

- Showroom floors

Why are rubber mats important?

- Anti-fatigue properties- they are best as they help workers feet from fatigue that’s good for ergonomics

- Rubber matting- because of their durability and hard-wearing, they can withstand high traffic

- Gym floors – rubber mats are a good product for gym flooring as they can protect the gym users from incurring maximum injury on the floor.

- Garage floors – rubber mats have high tensile strength and are best for garage floors which means the garage floors will be protected from Tyre and car weight